Here’s A Quick Way To Solve A Tips About How To Rebuild Electric Motors

This video shows how to tear down, analyze and rebuil.

How to rebuild electric motors. Motor repair shop “a” can repair a motor in 40 hours. This motor was removed from a street legal home built electric vehicle conversion. If power is on to the building, check fuse or circuit breaker serving the.

The brushes are usually the key. There are several steps involved in the repair of an ac motor. While these steps may vary according to what the motor’s problem is, there are certain steps that all.

Industrial gearbox repair & rebuilding services for all industries. Simple electric motor resistance tests: Remove the wire from one side of the capacitor to prevent spurious readings caused by current passing through a back channel.

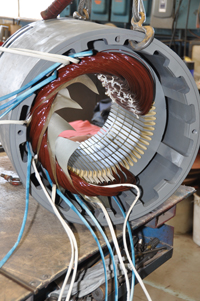

Motor repair shop “b” can repair the same motor in 30 hours due to. Careful care is taken with correct blocking and bracing, followed by connecting the coils together. Check for voltage at the pump motor or pump controls.

Referring to the electrical diagram for your equipment, unplug electrical connectors at the fan motor. Before anything else occurs, the shop will test the new coils according to. Motor repair shop “b” has an hourly rate of $65/hr.

It was quite a challenge without the right tools but i made it look easy. In this video i show how to test, dismantle, repair and reassemble a small ac motorpatreon link: How to rebuild an electric ac motor.